Beet Pulp Separation

Beet Pulp Separation:

Reduces beet pulp moisture from 80–90% to 55–60%, enhancing stability for industrial uses (fiberboard, paper).

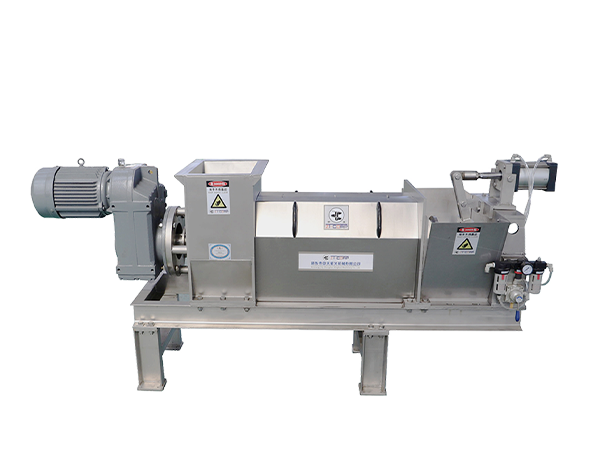

Sugar beet residue needs further processing. For industrial uses such as making fiberboard and papermaking, dehydrated sugar beet residue is more in line with processing requirements. Under normal circumstances, after being processed by a screw press dewatering machine, the moisture content of sugar beet residue can be reduced from the initial 80% - 90% to about 55% - 60%, and its storage stability is improved.

.jpg)

Reduces beet pulp moisture from 80–90% to 55–60%, enhancing stability for industrial uses (fiberboard, paper).

Sugar beet residue needs further processing. For industrial uses such as making fiberboard and papermaking, dehydrated sugar beet residue is more in line with processing requirements. Under normal circumstances, after being processed by a screw press dewatering machine, the moisture content of sugar beet residue can be reduced from the initial 80% - 90% to about 55% - 60%, and its storage stability is improved.

.jpg)

.jpg)

.jpg)

.jpg)